The new headquarters of the courier company MRW in L´Hospitalet de LLobregat is a perfect example of sustainable architecture and construction, respectful towards the environment. Evidence of this is the two BREEAM certifications with an EXCELLENT qualification in the design phase and BREEAM ES COMMERCIAL 2010 EXCELLENT qualification in the post-construction phase, something that had not occurred before in our country and is setting a positive precedent. These certifications guarantee the sustainability of the project, devised by the Barcelona firm Nomen i Associats Arquitectes.

Their proposal presents a building that pivots around three main values: Transparency in its relationship with the exterior, between its interior spaces and in the building itself; efficiency in the use of spaces, in their distribution, flexibility and operation; and commitment to the environment and sustainable management. This use of resources has been revealed in the construction of the building itself, for which preferably recyclable material resources have been used, in some cases up to 100%, such as aluminium. It is therefore a building that does not waste, on the contrary, it conserves and takes advantage of the generated energy.

Cortizo, an European benchmark in the design and manufacture of aluminium systems for architecture, is the system specialist chosen by Nomen i Associats Arquitectes to nurture this unique project. The R&D and Architecture and Engineering departments of the Galician firm have developed Ad Hoc the closing of the facades.

A building that changes color and shape in 30 seconds.

The biggest peculiarity of the building is, without a doubt, its envelope. The façades have a double glass skin on the inside and alternatively adjustable blades made of aluminium and wicker, which allow optimum control of the thermal conditions inside, protecting and taking advantage of solar radiation as necessary.

This enclosure, for which a thousand aluminium blades have been used, means an improvement in the habitability of the construction and a true example of design and modernity in terms of its conception, development and manufacture by CORTIZO, in close collaboration with the architecture studio Nomen i Associats Arquitectes and Don Aluminio Los González, company responsible for the installation of the systems.

It involves micro-perforated, mobile and motorized aluminium blades. They alternate with other wicker blades on an aluminium supporting structure and can be manipulated manually or mechanically depending on changes in the exterior light or interior air conditioning needs. Both series of blades have an anodized stainless steel finish which causes a different chromatic effect on the surface depending on the rotational movement to which they are subjected and the incidence of light on them. Its structure is made up of two bodies: the stem located in the rotation zone, a motor that facilitates movement (each motor moves 10 blades), and the body of the blade that reaches a dimension between 3.90 and 4,10 meters long. To manufacture this enclosure, CORTIZO has made a singular use of resources. Part of the resulting blades comes from the recycling of the excess material from the micro-perforation of the former, so that not one centimeter of aluminium has been discarded, obtaining more than 12% of the blades this way.

Drag control

CORTIZO is characterized by subjecting all its manufacturing processes to strict quality control and guaranteeing the final performance of each and every one of its systems. At the Company's headquarters, located in Padrón (A Coruña), it has a Technology Centre dedicated to research, development and innovation, which has modern and comprehensive laboratories and test benches. The blade system designed by Nomen i Associats Arquitectes for the MRW building has been developed and tested in this centre.

On this occasion, in addition to the usual control procedure in all CORTIZO manufacturing processes, a specific air drag test was added in order to observe the behavior of the system when it faces adverse meteorological phenomenon. In order to do this, the technicians of the Padrón firm measured the incidence and wind load on the surface of the building. "We study the weather history in the area in order to know the incidence of the wind and check the resistance that the blades should put up," says Domingo Brión, technical director of the Architecture and Engineering department of CORTIZO, who, allong with the company's R&D department and technicians from the Don Aluminio Los González installation company, carried out the control and quality tests for this project.

Consequently, after obtaining the relevant data, a special test is carried out in which the resistance level of the motors that move the blades and their safety against adverse weather incidents were analyzed. For this purpose, turbines capable of generating wind speeds greater than 100 km/hour were used. "It was a question of verifying the resilience of the motors to very strong winds," says Domingo Brión, "a test that the blades and the motors that move them passed satisfactorily. Our objective was, at all times, to rigorously check the resistance of the materials in these possible, but not probable, situations ”.

An avant-garde project

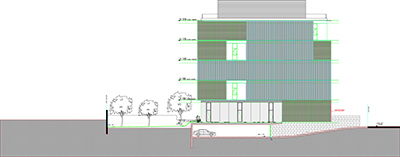

The construction is a rectangular floor plan volume that stands on a 1.20m high socle that occupies the entire area of operation. This peculiarity enables the building to have a single basement with a large number of parking spaces. The slope is smoothed in the area of the façade that faces Gran Vía, where the main entrance is located with a garden area, ramps and access stairs. The constructed area is 6,600 square meters distributed on the ground floor and 4 floors.

The building is presents itself as an open space around a central block that contains the patio, the vertical communication nucleus and the facilities. This solution allows the functional office area to always develop in direct contact with the façade area in which the CORTIZO window system, Cor-60 Hidden Sash, has been installed, with modulations of 3,350 mm in height, thus allowing to very effectively take advantage of Natural light thanks to its minimal aluminium cross-section of only 63 mm.

Sustainable and comfortable

Its very high degree of energy efficiency is reinforced by the installation of several CORTIZO systems with Thermal Break, in addition to the blade enclosure developed Ad Hoc by the firm. Thus, the building has COR 60 Hidden Sash and COR 60 windows and Millennium Plus pedestrian doors.

The Cor-60 Hidden Sash units have dimensions of 1,002 x 3,350 mm, with upper and lower fixed and tilt&turn opening in the central area, integrate perfectly into the glass-only skin that surrounds each of the floors of the building. In both cases, the defined glazing provides solar control and low emissivity to guarantee the minimum radiation absorptivity and lower transmittance values, which, in the case of this system and glass of 6/8/4+4 low emissions, does not exceed 1.9 W/m²K. In certain areas of the upper floors where pivoting openings were required, the Cor-60 system was installed.

The selection of CORTIZO systems for this project is completed with the Millennium Plus Door with Thermal Break, wich is an optimal system for entrance and pedestrian doors capable of supporting up to 500,000 opening and closing cycles and high acoustic and thermal performance obtained thanks to its large glazing capacity and low frame transmittance of only 2.5 W/m²K. All these CORTIZO systems have the appropriate characteristics to jointly improve the thermal inertia of a construction project as energy efficient as the MRW building.

Project:

Corporate Headquarters MRW Group

Location: Gran Via l'Hospitalet in Llobregat. Barcelona

Use: Bureau

Construction area: 6.600 square metres distributed in ground floor and 4 storeys.

Nomen i Associats Arquitectes

Silvia Crespo Nomen

Frederic Crespo Nomen

Solution used:

- Solar proction blades AD HOC (mobile and motorized micro-perforated aluminium blades, and wicker blades with an aluminium support structure).

- COR-60 Hidden Sash with RPT

- COR-60 with RPT - Millennium Plus Door with RPT

Installer:

Don Aluminio Los González